CNC Machining Precision Parts Industry: The Future of Manufacturing

CNC machining precision parts industry has been rapidly growing over the past few years. It has become an integral part of the manufacturing process, and its importance is only going to increase in the future. In this article, we will discuss the CNC machining precision parts industry, its benefits, and the future of manufacturing.

What is CNC Machining?

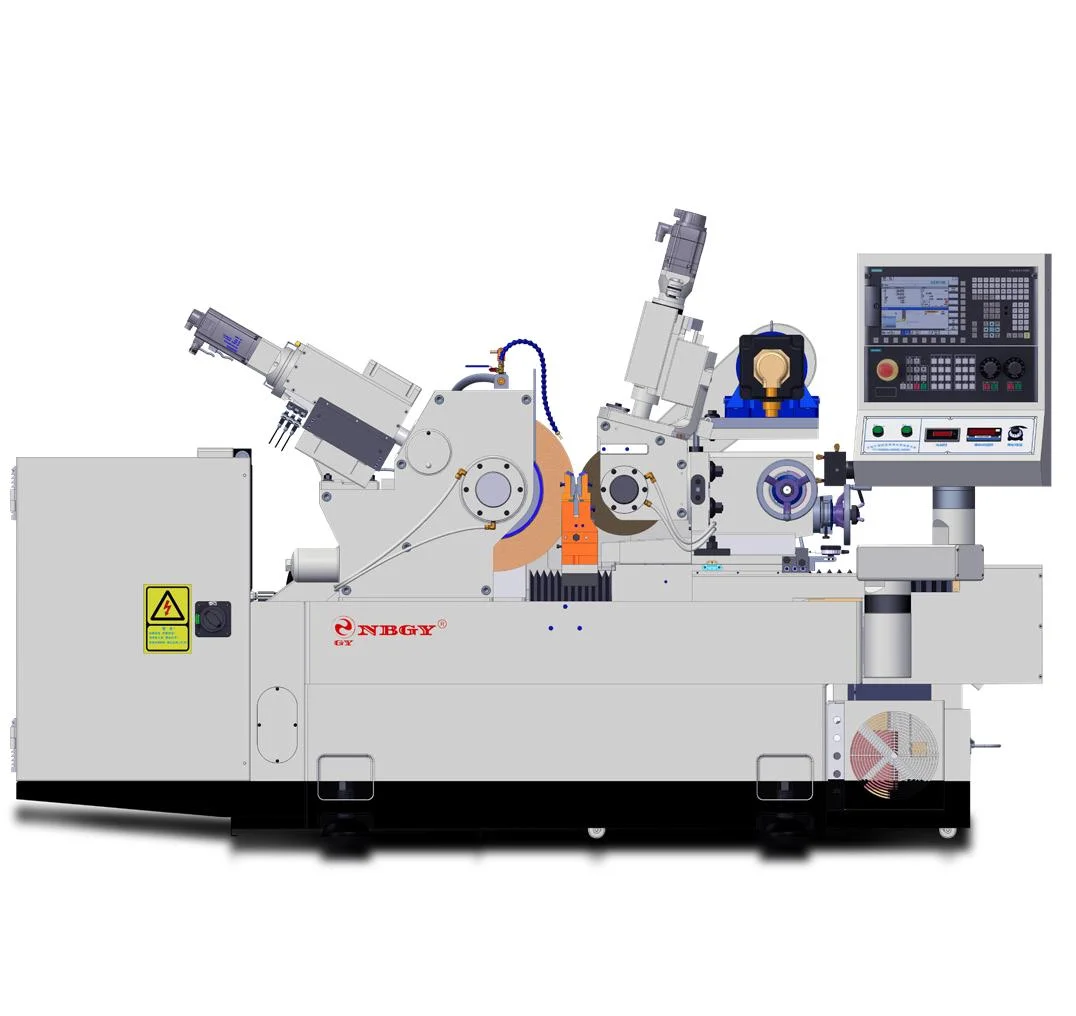

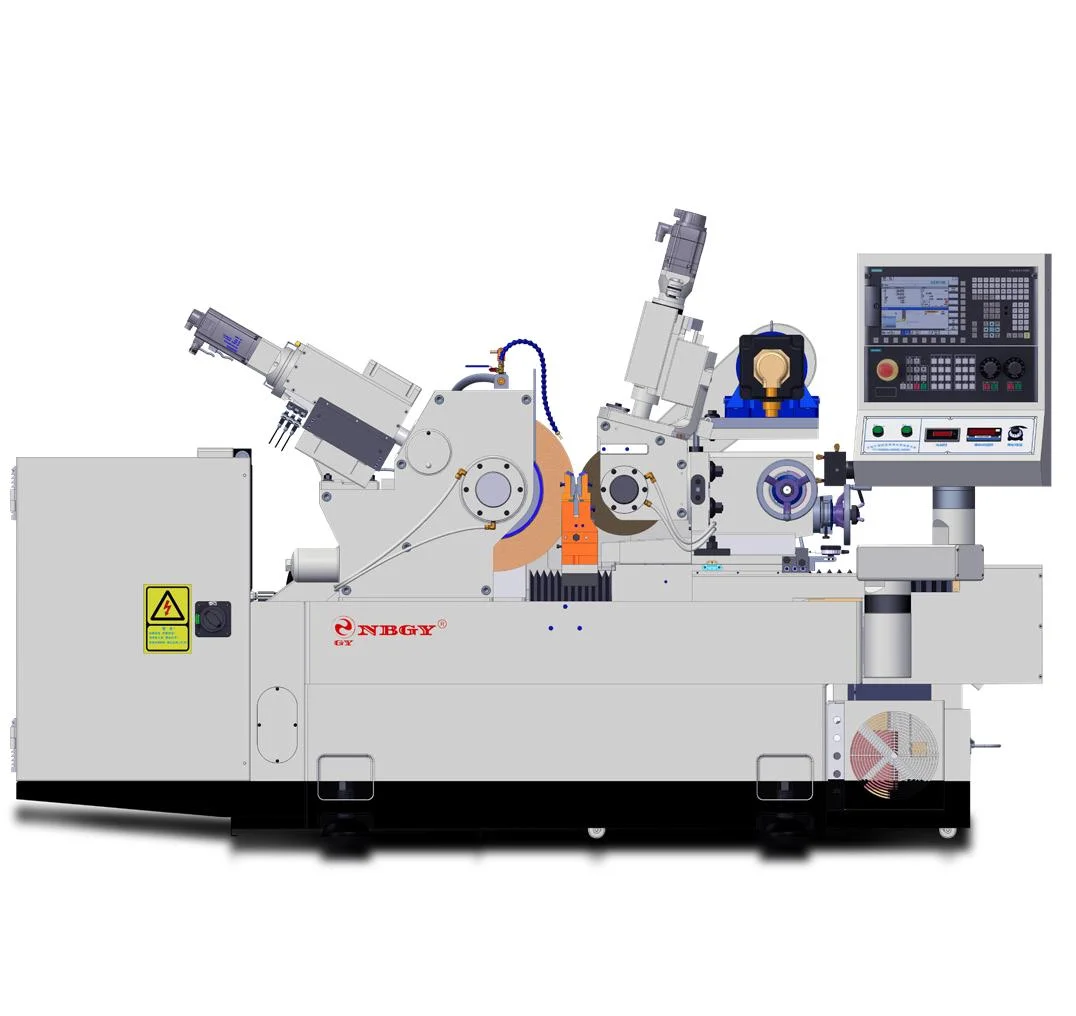

CNC (Computer Numerical Control) machining is a manufacturing process that involves the use of computers to control machine tools. It is used to create complex shapes and designs that are difficult or impossible to achieve with traditional manufacturing methods. The CNC machine reads the instructions from a computer program and uses them to control the movement of the machine tools. This allows for precise and accurate manufacturing of parts.

Benefits of CNC Machining Precision Parts Industry

There are several benefits of CNC machining precision parts industry:

1. Accuracy: CNC machines are incredibly accurate and can produce parts with very tight tolerances. This means that parts can be manufactured to exact specifications, reducing the need for manual adjustments and improving overall quality.

2. Speed: CNC machines can produce parts at a much faster rate than traditional manufacturing methods. This means that production times can be reduced, and more parts can be produced in a shorter amount of time.

3. Cost-effective: CNC machining is a cost-effective manufacturing method. Once the program is set up, the machine can run for extended periods without any additional labor costs. This means that the cost per part decreases as the volume of production increases.

4. Flexibility: CNC machines can be programmed to produce a wide range of parts with different shapes and sizes. This means that they can be used to manufacture a variety of products, making them a versatile manufacturing method.

Future of Manufacturing

The future of manufacturing is closely tied to the CNC machining precision parts industry. As technology continues to advance, CNC machines will become even more advanced, allowing for even greater precision and accuracy. Here are some of the ways in which CNC machining will shape the future of manufacturing:

1. Automation: With the increasing use of robotics and automation, CNC machines will become even more efficient and cost-effective. This will lead to greater productivity and reduced labor costs.

2. 3D Printing: 3D printing is a rapidly growing technology that has the potential to revolutionize the manufacturing industry. CNC machines can be used in conjunction with 3D printing to produce complex parts with incredible accuracy.

3. Artificial Intelligence: As AI technology continues to advance, it will be integrated into CNC machines, allowing them to learn and adapt to new manufacturing processes. This will lead to even greater efficiency and accuracy.

4. Sustainability: CNC machining is a sustainable manufacturing method, as it produces less waste and uses fewer resources than traditional manufacturing methods. As sustainability becomes an increasingly important issue, CNC machining will become even more important in the manufacturing industry.

Conclusion

The CNC machining precision parts industry is a vital part of the manufacturing process. It offers several benefits, including accuracy, speed, cost-effectiveness, and flexibility. As technology continues to advance, CNC machines will become even more advanced, leading to greater productivity, efficiency, and sustainability. The future of manufacturing is closely tied to the CNC machining precision parts industry, and it will continue to shape the industry for years to come.